Factory Cheap Hot Tunnel Iqf - Tunnel IQF Quick Freezer – INCHOI

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for Vacuum Fried Chips Machine, Automatic Vacuum Packing Machine, Vacuum Deep Fryer, Our tenet is clear all the time: to deliver high quality product at competitive price to customers around the world. We welcome potential buyers to contact us for OEM and ODM orders.

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for Vacuum Fried Chips Machine, Automatic Vacuum Packing Machine, Vacuum Deep Fryer, Our tenet is clear all the time: to deliver high quality product at competitive price to customers around the world. We welcome potential buyers to contact us for OEM and ODM orders. Factory Cheap Hot Tunnel Iqf - Tunnel IQF Quick Freezer – INCHOI Detail:

TUNNEL FREEZER

Product advantages:

1.Use imported PIC controller

2.Small size, energy saving, reliable performance

3.Simple structure, convenient operation, long service life

4.Compressed by imported equipment and stainless steel spring wire, the surface is flat, the value of the mesh belt can be selected according to the requirements

5.Adopt heat wave blowing method, high freezing efficiency

6.Single or double mesh belt combination can be selected according to output requirements

7.Use water flushing to ensure cleanliness and hygiene

8.The imported frequency converter realizes stepless speed regulation, and the freezing time of frozen products can be adjusted continuously according to the needs, which can be adapted to the processing of various frozen products.

9.The library body is made of rigid polyurethane foam, which has good thermal insulation performance. The inner and outer brackets and the inner and outer brackets of the library are made of stainless steel, which is easy to clean.

|

Model |

Dreezing capacity(KG/H) |

Cold consumption(KW) |

Installed power(KW) |

Length |

value |

Height |

Mesh belt value |

|

IQF -100 |

100 |

15 |

2.3 |

7 |

1.5 |

2.1 |

1 |

|

IQF -150 |

150 |

21.5 |

3 |

8 |

1.8 |

2.2 |

1.3 |

|

IQF -300 |

300 |

43.5 |

6.5 |

12 |

2.3 |

2.3 |

1.8 |

|

IQF -500 |

500 |

75 |

10.3 |

13.5 |

3 |

2.5 |

2.5 |

|

IQF -1000 |

1000 |

142 |

19.8 |

21.5 |

3 |

2.5 |

2.5 |

|

IQF -2000 |

2000 |

278 |

38 |

29.2 |

4.1 |

2.5 |

2.5 |

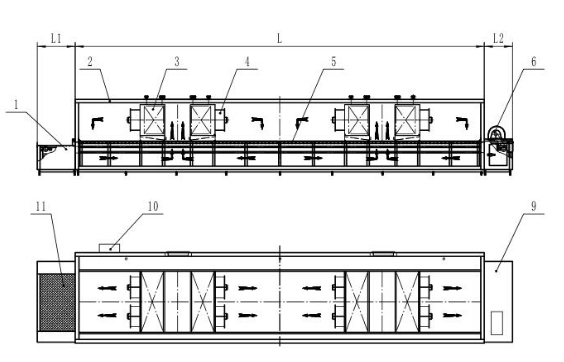

Structure drawing

1. Inlet frame

2. Insulation panel

3. Evaporator

4. Fan

5. Air deflector

6. Drive reducer

7. Inside passage

8. ss supportor

9. Outlet frame

10. Electric control panel

11. Mesh belt

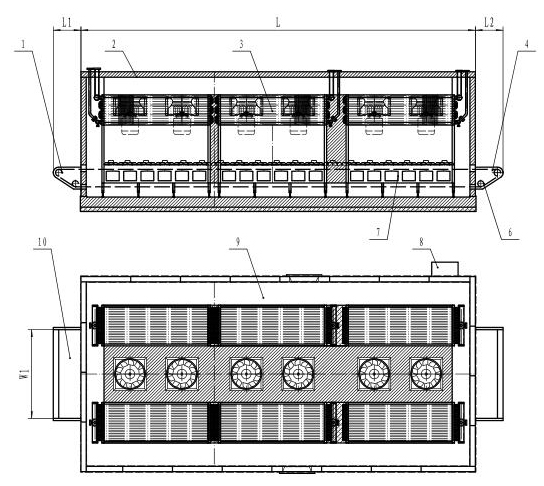

Structure drawing

1. Inlet frame

2. Insulation panel

3. Evaporator

4. Outlet frame

5. Centrifugal fan

6. Drive reducer

7. Air deflector

8. Electric control panel

9. Inside passage

10. Mesh belt

Product detail pictures:

Related Product Guide:

Our eternal pursuits are the attitude of "regard the market, regard the custom, regard the science" and the theory of "quality the basic, trust the first and management the advanced" for Factory Cheap Hot Tunnel Iqf - Tunnel IQF Quick Freezer – INCHOI , The product will supply to all over the world, such as: Bahamas, Ghana, Palestine, We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

The factory technical staff gave us a lot of good advice in the cooperation process, this is very good, we are very grateful.