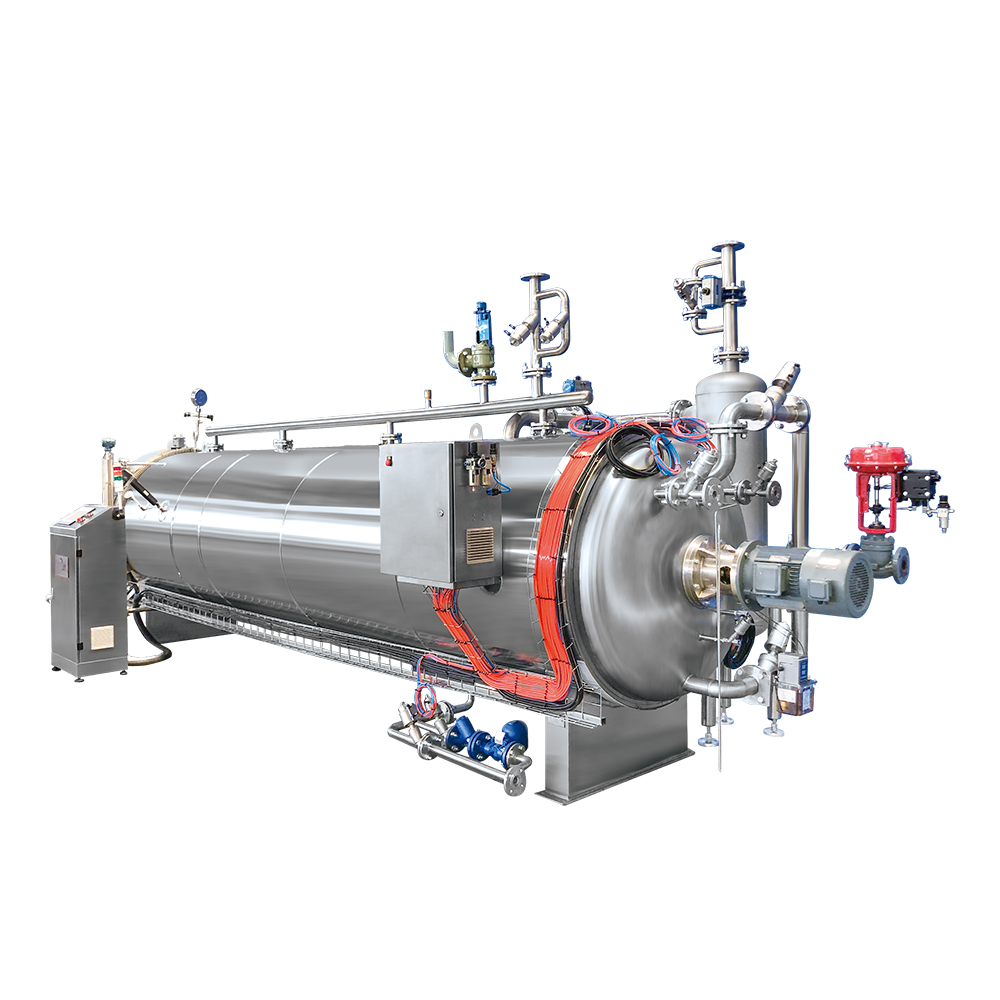

Chinese Professional Retort Technology - Steam and AIR RETORT – INCHOI

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Continuous Fryer Machine, Vacuum Pouch Sealing Machine, Bottle Washing Machine In Pharmaceutical Industry, We are devoted to provide professional purification technology and solutions for you!

We depend on sturdy technical force and continually create sophisticated technologies to meet the demand of Continuous Fryer Machine, Vacuum Pouch Sealing Machine, Bottle Washing Machine In Pharmaceutical Industry, We are devoted to provide professional purification technology and solutions for you! Chinese Professional Retort Technology - Steam and AIR RETORT – INCHOI Detail:

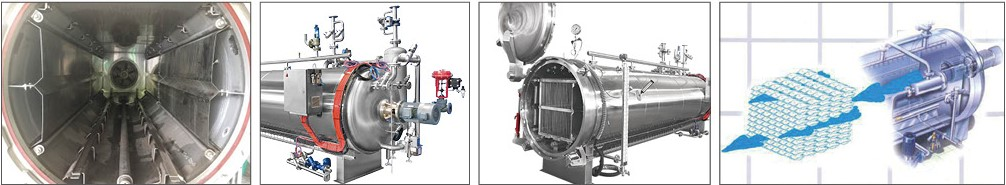

Applicable Scope:

Flexible packaging, bottled, tinplate cans (canned luncheon meat, canned tuna, etc.), standing bags, aluminum foil boxes, cups and bowls of snack foods, meat products, beverages and other high-temperature sterilization products.

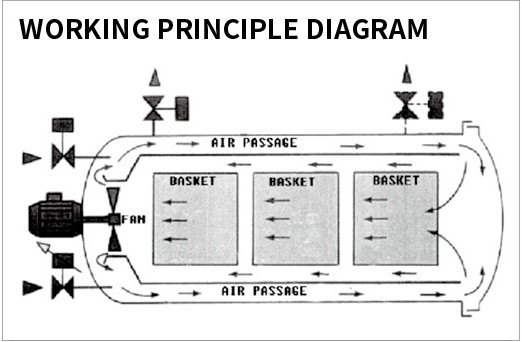

Working principle diagram:

Performance features:

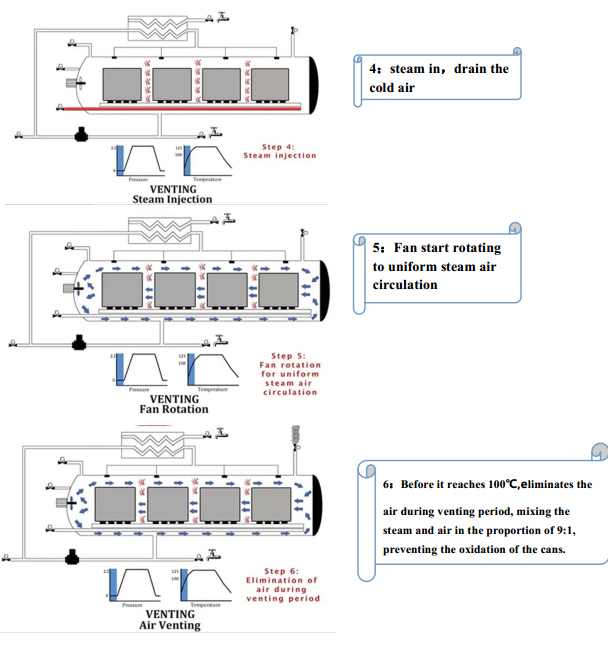

1. Compressed air is injected into the retort, and the turbo fan rotates to break the cold air mass , The mixture of steam and air is forced to circulate in the retort, for thorough sterilization and saving over 15% steam;

2. With dual pressure & temperature sensors and over pressure&temperature alarm function, it can better protect equipment and products;

3. Flexible control of pressure and temperature, realize cooling with counter pressure.

Advantage

●Accurate temperature control, excellent heat distribution

The temperature control module has up to 12 stages of temperature control, and the step or linearity can be selected according to different products and process recipe heating modes, so that the repeatability and stability between batches of products are maximized well, the temperature can be controlled within ±0.3℃. Steam enter the chamber while circulating fans ensures a proper temperature in the chamber. Sterilization is carried for preset temperature level & time.

●Rapid heating

No need to heat other media (such as hot water), the heating rate is very fast.

●Perfect pressure control, suitable for a variety of packaging forms

The pressure control module continuously adjusts the pressure throughout the whole process to adapt the internal pressure changes of the product packaging, so that the degree of deformation of the product packaging is minimized, regardless of the rigid container of tin cans, aluminum cans or plastic bottles, plastic boxes or flexible containers can be easily satisfied, and the pressure can be controlled within ±0.05Bar.

●Save energy saving and protect environment

The steam is directly heated, no exhaust is needed, and the minimum steam loss.

Low noise, create a quiet and comfortable working environment.

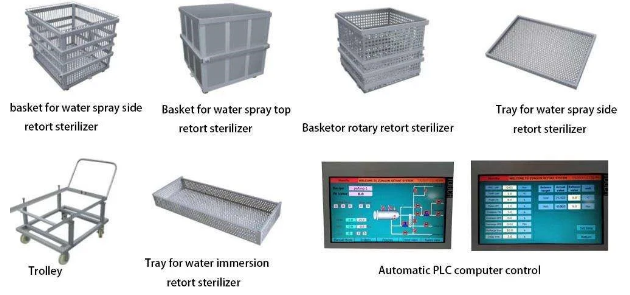

Product detail pictures:

Related Product Guide:

Our pursuit and company goal is to "Always satisfy our customer requirements". We continue to develop and design superior quality products for both our old and new customers and achieve a win-win prospect for our clients as well as us for Chinese Professional Retort Technology - Steam and AIR RETORT – INCHOI , The product will supply to all over the world, such as: French, Mexico, Milan, We sincerely hope to cooperate with customers all over the world, if you would like to have more information, please kindly contact us, we are looking forward to building up a great business relationship with you.

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.