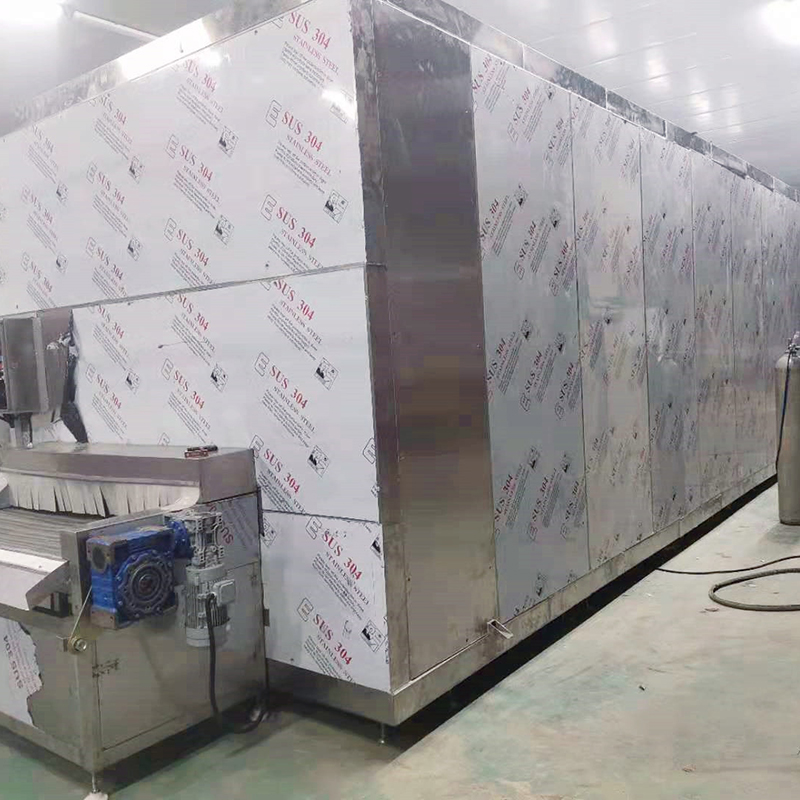

2021 China New Design Vacuum Food Packaging - High-speed impact IQF tunnel freezer – INCHOI

Our company sticks to the principle of "Quality is the life of the company, and reputation is the soul of it" for Spiral Iqf, Chamber Vacuum Packing Machine, Autoclave Food Processing, On account of superior quality and competitive price , we will be the market leader, please don’t hesitate to contact us by phone or email, if you are interested in any of our products.

Our company sticks to the principle of "Quality is the life of the company, and reputation is the soul of it" for Spiral Iqf, Chamber Vacuum Packing Machine, Autoclave Food Processing, On account of superior quality and competitive price , we will be the market leader, please don’t hesitate to contact us by phone or email, if you are interested in any of our products. 2021 China New Design Vacuum Food Packaging - High-speed impact IQF tunnel freezer – INCHOI Detail:

FLUIZED QUICK FREEZER

Product Description:

The INCHOI High-speed impact IQF tunnel freezer adopts an advanced design independently developed, which is efficient in freezing during operation and energy-saving in operation.

INCHOI high-speed impact technology breaks the traditional concept of rapid cooling only by increasing the wind speed, and greatly shortens the freezing time.

Suitable for individual quick freezing of thin, flat products and small-volume bulk products. The material enters from the entrance, and the upper and lower sides collide and expand through high-speed cold air at the same time, absorb heat, and quickly cool down, so as to ensure two-way freezing of food and achieve the purpose of rapid freezing.

Structural features

1. INCHOI’s high-speed impact freezer meets the requirements of HACCP, and the equipment materials meet the food safety regulations.

2. The “two-way cold air impact technology” breaks the traditional technical constraints of increasing wind speed and cooling, and the freezing time is greatly shortened. The efficiency of freezing fish fillets is more than double that of the traditional individual freezer; the time for freezing shrimp is more than two to three times shorter than that of the traditional individual freezer.

3. The loss of cooling capacity is small, the quick-freezing effect is improved, and the energy is saved.

4. The design of the quick-freezer is reasonable, easy to clean, and has no dead ends.

5. The mesh surface of the mesh belt is flat, which can ensure the shape and appearance quality of the product.

6. The mesh belt adopts frequency conversion reducer, which can adjust the freezing time and traveling speed according to the requirements of different foods.

7. The product can be frozen directly on the mesh belt, or it can be frozen on the plate, it can be single frozen, bag frozen or tray frozen.

|

Model |

Capacity/hour |

Freezing time (min) |

Feed temperature |

Discharge temperature |

Temperature inside |

| YCDZ-300 | 300KG | 20-40 | ≤40 | -18℃ | -35℃ |

| YCDZ-500 | 500KG | 20-40 | ≤40 | -18℃ | -35℃ |

| YCDZ-1000 | 1000KG | 20-40 | ≤40 | -18℃ | -35℃ |

| YCDZ-2000 | 2000KG | 20-40 | ≤40 | -18℃ | -35℃ |

Product detail pictures:

Related Product Guide:

Using a complete scientific high quality management program, superior high quality and superior faith, we acquire great reputation and occupied this industry for 2021 China New Design Vacuum Food Packaging - High-speed impact IQF tunnel freezer – INCHOI , The product will supply to all over the world, such as: El Salvador, Namibia, America, We have been in operation for more than 10 years. We are dedicated to quality products and consumer support. We currently own 27 product utility and design patents. We invite you to visit our company for a personalized tour and advanced business guidance.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!